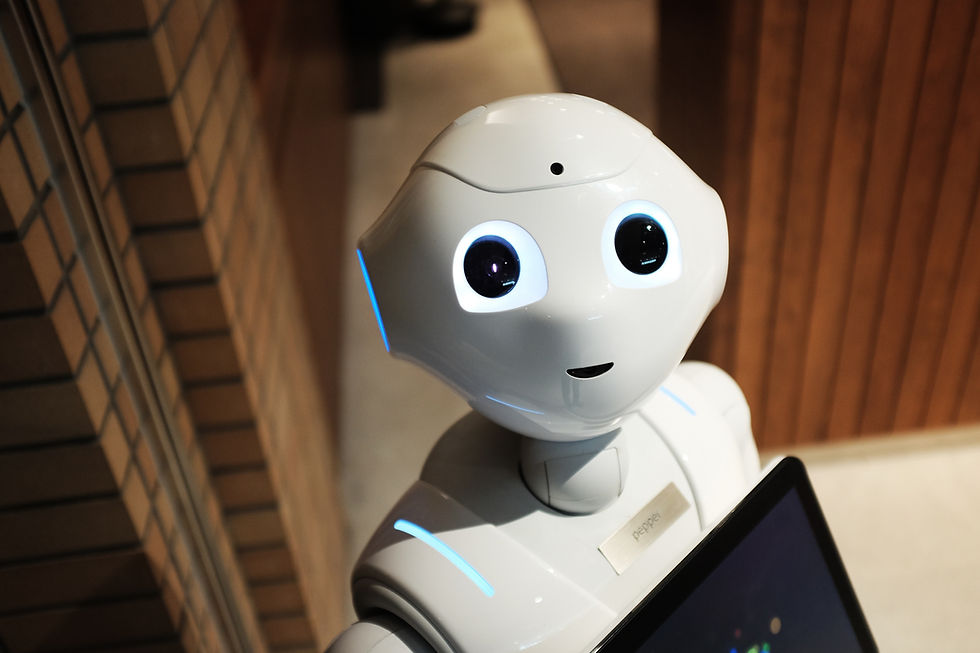

The integration of Artificial Intelligence (AI) into CMM programming is rapidly transforming the field of metrology. AI-driven tools are helping manufacturers automate inspection tasks, optimize measurement routines, and enhance the precision of CMM operations. By using machine learning algorithms, AI can predict and adapt to various factors, such as part deformation or material properties, making the inspection process more robust and efficient.

Benefits of AI in CMM Programming

Automating Routine Tasks: AI can automatically generate CMM programs based on the CAD model and GD&T requirements, reducing the time spent on manual programming. This is especially useful for complex parts or large production runs.

Collision Avoidance: Advanced AI algorithms can detect potential collisions between the probe and the part during program simulation, allowing the programmer to adjust paths before running the program on the actual machine.

Adaptive Measurement Strategies: AI can analyze the results of previous measurements and adapt the inspection routine to focus on critical areas that have historically shown high variability, improving the accuracy and efficiency of the inspection process.

Real-Time Data Analysis: AI can process large volumes of measurement data in real time, making it easier to spot trends and deviations from acceptable standards, enabling proactive adjustments to the manufacturing process.

AI-Driven Metrology in Practice

In industries such as aerospace, automotive, and motorsport, AI is not just about speeding up CMM programming but also about improving overall quality control. By incorporating AI, companies can reduce scrap rates, avoid production bottlenecks, and enhance the accuracy of first-off inspections. Experienced programmers like CMM Programming Dan can harness AI's capabilities to provide clients with cutting-edge solutions for CMM programming, making inspection processes faster and more reliable.

Comentarios